Competent, reliable, experienced

EVERYTHING FROM A SINGLE SOURCE

Our process engineers develop process engineering solutions for the purification and drying of gases and liquids, for the conditioning and liquefaction of biogas and natural gas as well as for exhaust air purification and solvent recovery. Engineering, manufacturing and assembly of the plant take place on our company premises in Berlin. The process control system implemented by our commissioning engineers completes the turnkey process plant.

Competent, reliable, experienced

EVERYTHING FROM a single SOURCE

Our process engineers develop process engineering solutions for the purification and drying of gases and liquids, for the conditioning and liquefaction of biogas and natural gas as well as for exhaust air purification and solvent recovery. Engineering, manufacturing and assembly of the plant take place on our company premises in Berlin. The process control system implemented by our commissioning engineers completes the turnkey process plant.

Adsorptive Drying Plants

for Gases and Liquids

GAS AND LIQUID DRYING FOR A WIDE RANGE OF APPLICATIONS

Almost all gases can be dried by adsorption. By optimising the process design and selecting suitable adsorbents, dew point temperatures of below -80 °C can be achieved. In combination with a SILPURE gas purification process, the removal of other undesirable components is possible in addition to dehydration.

In addition to common process gases such as hydrogen, oxygen, nitrogen and carbon dioxide, we have extensive experience in drying hydrochloric acid, sulfur dioxide, hydrogen sulfide, ammonia, vinyl bromide, acetylene and many other compounds.

A special case of adsorptive drying is water removal from liquids. In combination with the PERVAP ™ membranes used by SILICA, the water content in solvents can be reduced from 30 % down to 1 ppm.

Adsorptive Drying Plants

for Gases and Liquids

GAS AND LIQUID DRYING FOR A WIDE RANGE OF APPLICATIONS

Almost all gases can be dried by adsorption. By optimising the process design and selecting suitable adsorbents, dew point temperatures of below -80 °C can be achieved. In combination with a SILPURE gas purification process, the removal of other undesirable components is possible in addition to dehydration.

In addition to common process gases such as hydrogen, oxygen, nitrogen and carbon dioxide, we have extensive experience in drying hydrochloric acid, sulfur dioxide, hydrogen sulfide, ammonia, vinyl bromide, acetylene and many other compounds.

A special case of adsorptive drying is water removal from liquids. In combination with the PERVAP ™ membranes used by SILICA, the water content in solvents can be reduced from 30 % down to 1 ppm.

Catalytic and adsorptive Purification Plants for Gases

EFFICIENT AND POWERFUL SYSTEMS FOR GAS PURIFICATION

To remove oxygen, hydrogen, carbon monoxide or hydrocarbons from process gases, a platinum/palladium catalyzed reaction to water or carbon dioxide can be used. The reaction products can be removed by downstream adsorption on molecular sieves.

Gas polishing catalytically eliminates traces of arsenic hydrogen (arsine), monophosphane (phosphine) or carbonyl sulfide (COS), which is of great importance for the purification of monomers such as ethylene or propylene prior to polymerization.

When designing the purification processes, SILICA can draw on products from well-known catalyst manufacturers. Our customers can obtain a desired catalyst system or they can rely on SILICA’s expertise and experience in selecting an optimal catalyst.

SILICA can look back on a history of more than 80 years in the design and construction of hydrogen purification plants. For the production of green hydrogen, we develop and manufacture sophisticated, tailor-made hydrogen purification plants that are perfectly adapted to the requirements of the electrolysers.

Plants for the liquefaction

of bio- and natural gas

TURNKEY GAS LIQUEFACTION PLANTS

FOR A WIDE RANGE OF CAPACITIES

In the field of gas liquefaction, SILICA cooperates with the Spanish company ADDsynergy. Within the framework of the successful partnership, SILICA concentrates on the design and construction of the gas purification system, while ADDsynergy focuses on the liquefaction of the gas in question.

For the liquefaction of biogas, ADDsynergy has developed an innovative cascaded liquefaction process, which allows the efficient liquefaction of even small biogas flows starting from 300 m³/h. With this technology, the liquefied biogas (LBG) can be used as a green fuel, e.g. for heavy-duty transport.

Exhaust air purification

and solvent recovery

EFFICIENT ACTIVATED CARBON PLANTS

FOR VOC REMOVAL

For the separation of VOCs (Volatile Organic Compounds) from industrial exhaust air, SILICA offers activated carbon plants which are regenerated either with steam or also with inert gases. The recovered solvents (VOCs) can be reprocessed by rectification, air or steam stripping and reintroduced into the production process. SILICA designs and builds plants with an exhaust air flow rate of up to 300,000 m³/h. The residual VOC content of the purified exhaust air is less than 20 mg/m³.

For special applications, SILICA also offers pressure swing adsorption plants (PSA) for exhaust air purification. These are often used in tank farms as a second stage downstream of a membrane system.

A process for the purification of slightly polluted exhaust air with a VOC concentration between 30 and 300 mg/m³ completes SILICA’s technologies for exhaust air purification. Activated fibers are used to retain the smallest amounts of VOCs, which are then concentrated when the fibers are regenerated.

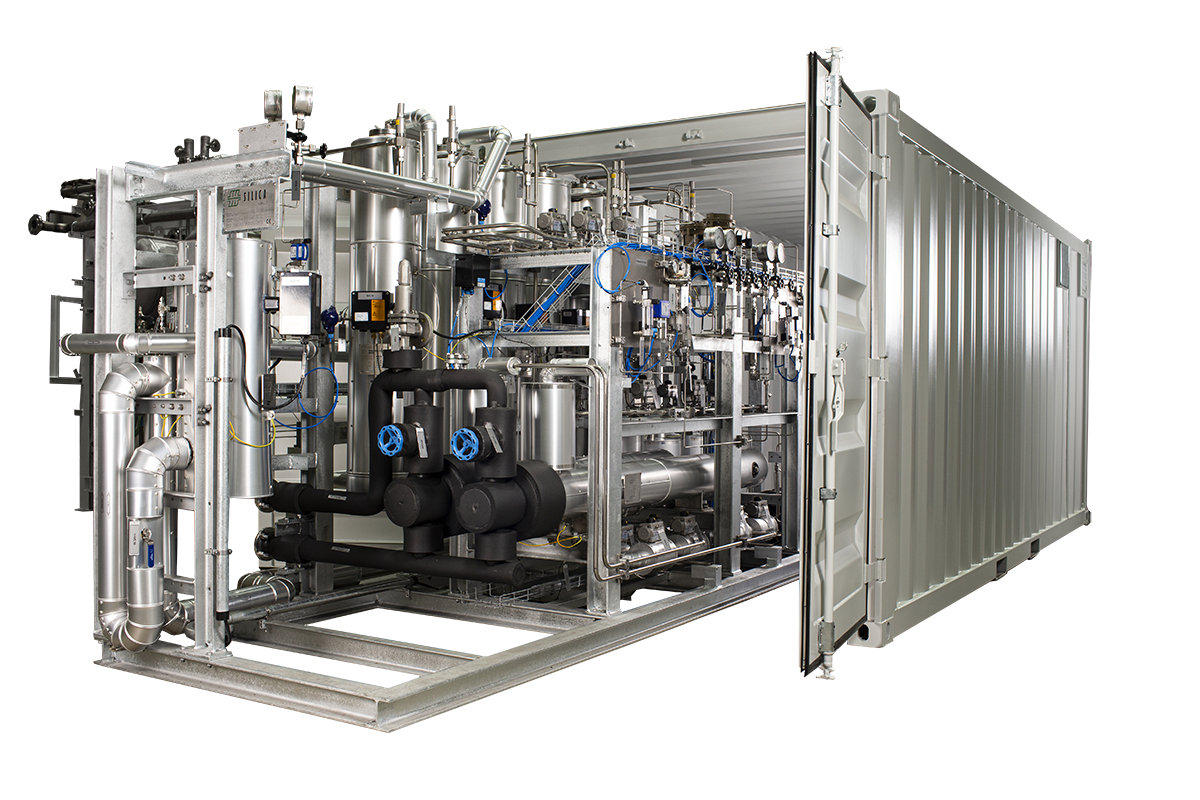

Experimental Plants from

TAILOR-MADE INNOVATIVE TEST

AND PILOT PLANTS

Trial or pilot plants are often used for the development and scale-up of new processes. The knowledge and data gained from the trials provide an important basis for scaling up the process, but also for the economic evaluation of the process.

The planning of test and pilot plants is often very demanding, since a high degree of flexibility and accessibility must be realized in a usually limited space. With decades of experience, SILICA can draw on extensive know-how in the design and manufacture of modular test and pilot plants. On request, the fully automated plants can also be installed in standard containers, which considerably simplifies transport and operation of the plants.

Our experienced and competent engineers will be pleased to support you in the planning and construction of your test or pilot plant.

Your contact to SILICA

SILICA: INDIVIDUAL, COMPETENT, RELIABLE

We treat every request confidentially and conscientiously. We want you to be

completely satisfied with our work!