Precise, sophisticated, smart

ENGINEERING, PIPE STRESS ANALYSIS AND STRENGTH CALCULATION

Do you need engineering support for the implementation of your project idea or are you interested in the

complete engineering of your process plant? SILICA offers a comprehensive package of engineering services

tailored to your individual needs. This ranges from process engineering, basic and detail design to pressure

vessel design, strength calculations and pipe stress analysis.

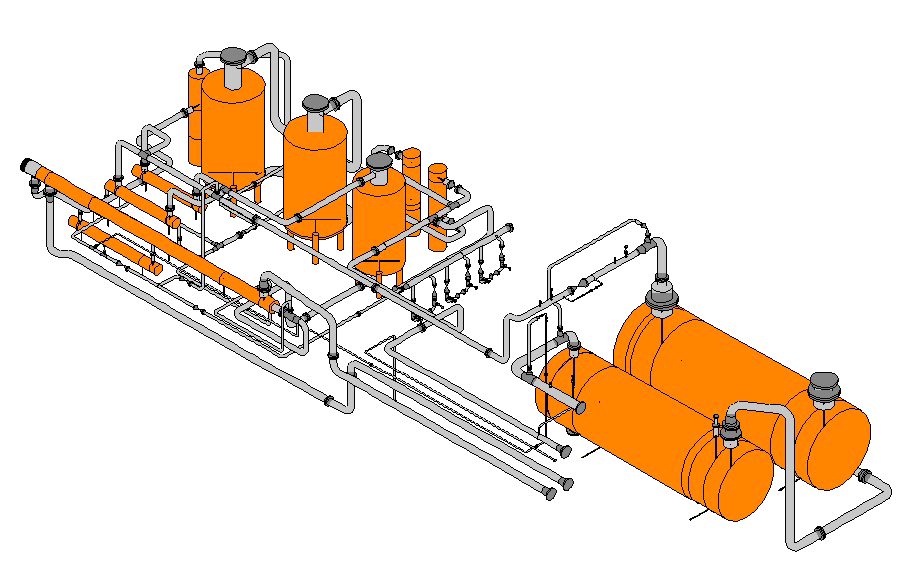

BASIC AND DETAIL ENGINEERING

Basic engineering refers to all engineering services that occur during the planning phase of the construction of plants, steel structures, pipeline structures and other industrial structures.

Whether modernisation, integration of technologies in existing plants or planning and erection of a completely new plant – our scope of services includes the dimensioning and technical design of foundations, steel and plant construction as well as I&C technology. For this purpose, SILICA coordinates and carries out a wide range of sections (e.g. plant engineering, process engineering, electrical engineering etc.).

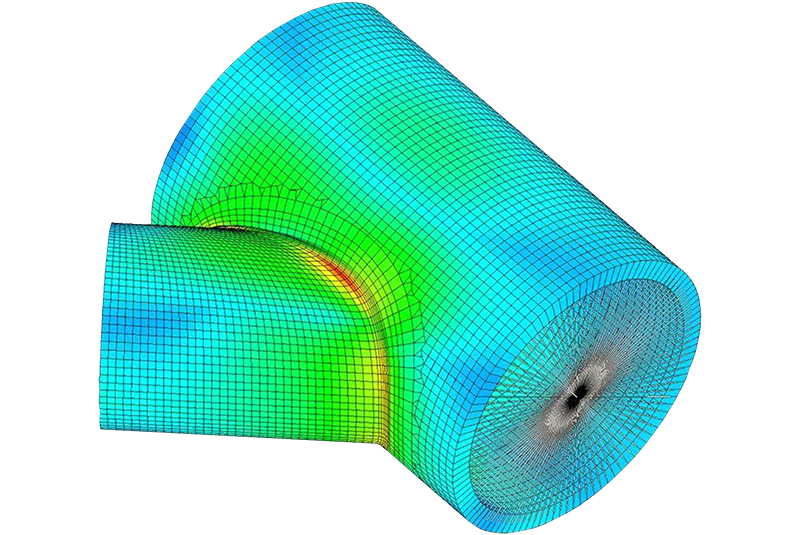

PIPE STRESS ANALYSIS

Pipe static calculations are used to calculate the stresses and deformations that occur for expected loads and installation conditions in order to be able to assess safety.

At SILICA, the pipe static calculations are carried out with the ROHR2 programme, whereby in addition to the loads from dead weight and operation, other static and dynamic loads such as wind, ice and snow loads, but also earthquake or pressure surge loads can be examined.

Further options for the pipe stress analysis are the configuration of bearings and compensators, the strength calculation of vessel components (e.g. branches, T-pieces, nozzles or bottoms) and the determination of equivalent stresses for steel structures.

Calculation standards: FDBR guideline “Calculation of power plant pipelines”, EN 13480-3, ASME B31.1, B31.3, B31.4 and B31.8, Stoomwezen D1101, Codeti 2006, RCC-M Cl. 1 to 3, ASME Cl.1 to 3, KTA 3201.2 and 3211.2, EN 13941, AGFW 1989, plastic pipes according to AFGW FW401, BS 7159, KRV, ISO14692, stresses for FE structures according to AD S4, EN 13445-3 Anh. C, ASME VIII Div 2 Part 5

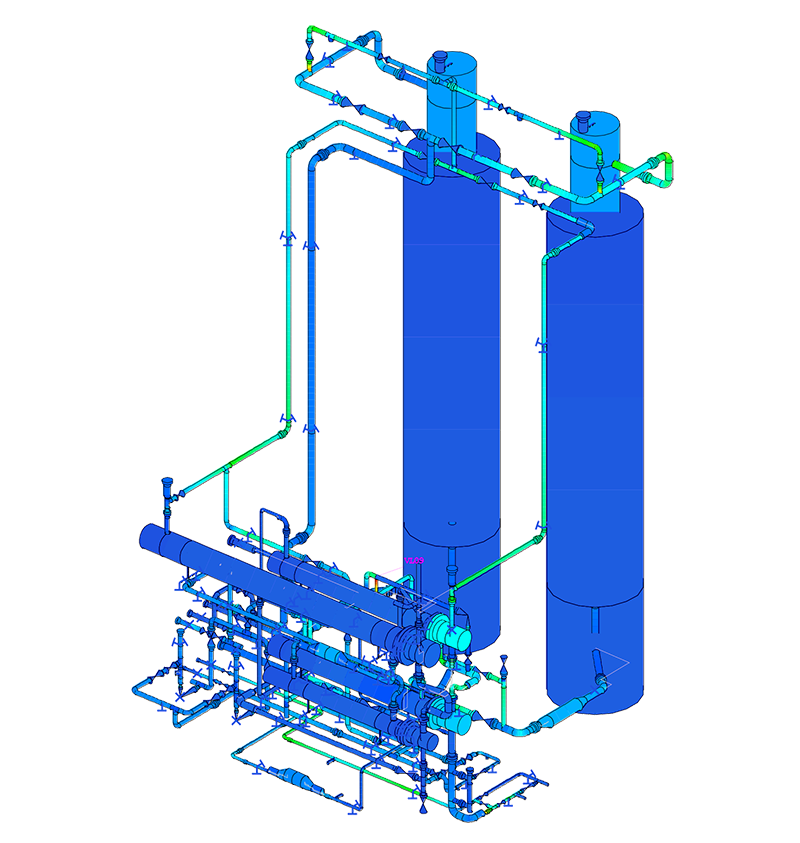

STRENGTH CALCULATION

Strength is the mechanical resistance of a body that a component, e.g. a screw or a bolt, puts up against a load. This load can be elastic or plastic, i.e. after the load the body returns to its original position (elastic) or it remains permanently deformed (plastic).

The design of a component depends primarily on the type of failure, which is usually caused by unacceptable deformations, forced rupture, fatigue fracture, wear or corrosion.

At SILICA, the strength calculations are carried out with the software PROBAD and ROHR2.

Besides pipe, flange and vessel calculations also pipe components (e.g. reducers, fittings, branches and manifolds) and vessel components (e.g. nozzles, bottoms, skirt supports, support pads, vessel feet and heat exchangers) are calculated.

Calculation standards: AD 2000, EN 13480-3, EN 13445-3, ASME VIII, ASME B31.1, ASME B31.3, EN 1591

Your contact to SILICA

SILICA: INDIVIDUAL, COMPETENT, RELIABLE

We treat every request confidentially and conscientiously. We want you to be

completely satisfied with our work!