Experience, tradition, innovation

IN BERLIN FOR OVER 90 YEARS

Experience, tradition, innovation

IN BERLIN FOR OVER 90 YEARS

Over 90 years of silica: a success story

Founding years: from crisis to success

Berlin, 1929: The city has more than four million inhabitants and the population is growing rapidly.

Around 82,000 motor vehicles are registered in Berlin.

Tempelhof Airport develops into Europe’s most modern air hub and records more than 20,800 landings that year.

The city is a melting pot of culture, economic boom and political conflict in the final years of the Weimar Republic.

Berlin is a symbol of the Golden Twenties between the end of inflation and the beginning of the Great Depression.

Berlin is hit by the global economic crisis.

In February 1929, 450,000 people are unemployed and there are 664 bankruptcies in the city.

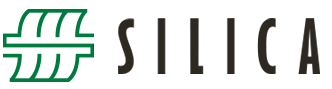

In this environment, the founding of SILICA Gel Gesellschaft m.b.H. is decided on April 26, 1929 and entered in the commercial register on May 6, 1929.

The sole shareholder is the US American SILICA Gel Corporation with a capital of 300,000 Reichsmark.

SILICA Gel Gesellschaft further develops the adsorption systems designed by Borsig and sells solvent recovery systems for the artificial leather and hard paper industry.

Takeover by German management

Due to the ongoing global economic crisis, the US-based SILICA Gel Corporation sells its shares to the engineers Adolf Koopmann, Fritz Krull and Dr. Kurt von Lüde in 1935.

With the purchase, the process documentation and patents for the production of the drying agent Silica Gel also pass into the possession of the new company.

In the following years, the production of Silica Gel is expanded at the Chemische Werke Coswig (Saxony-Anhalt).

In 1936, the company moved into larger business premises on Reichskanzlerplatz (today’s Theodor-Heuss-Platz) and the design department and physical laboratory were expanded.

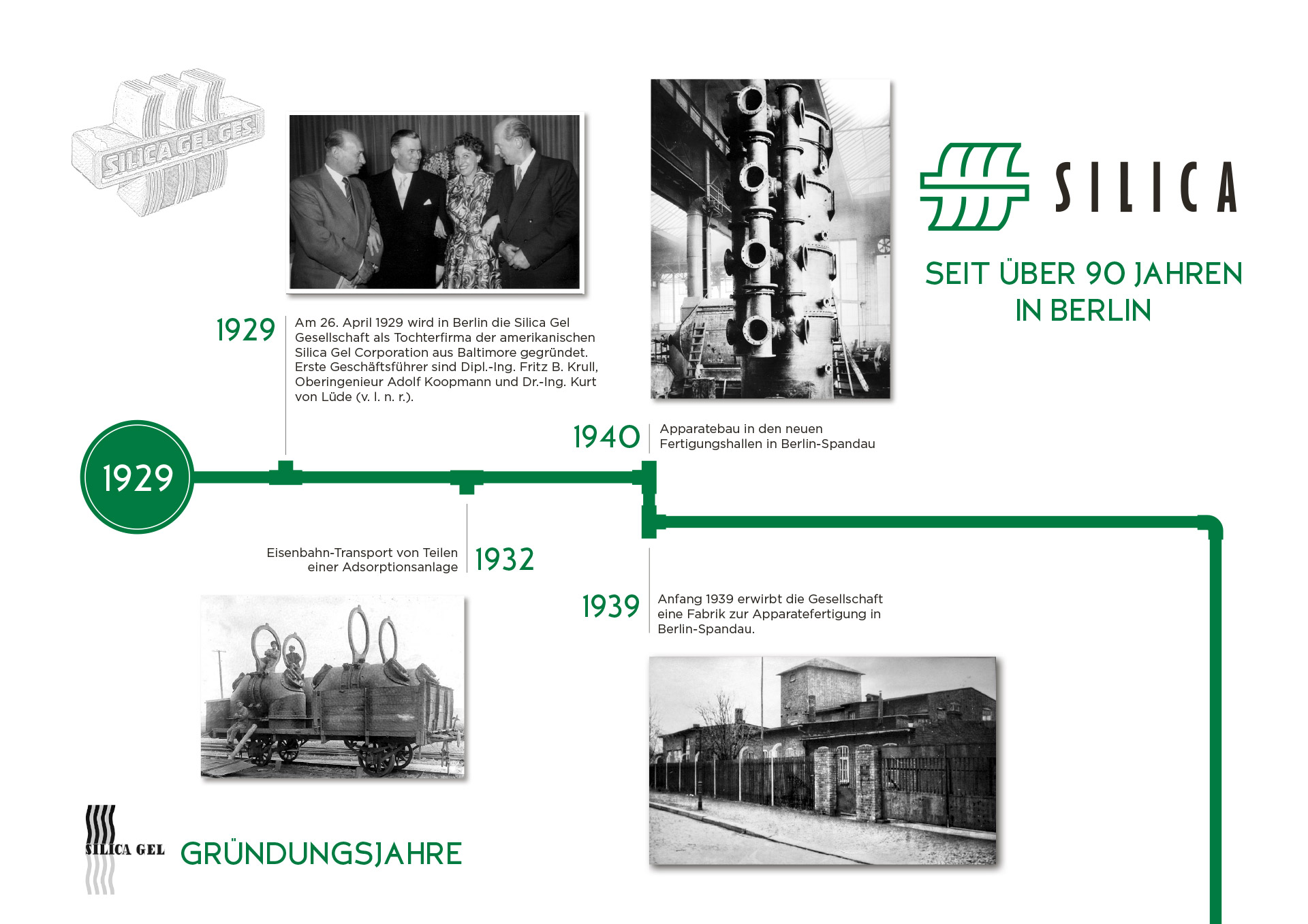

At the beginning of 1939, the company acquired a factory in Berlin-Spandau and began manufacturing its own apparatus and equipment.

RECONSTRUCTION

After the end of the Second World War, the authorities confiscate the business premises on Reichskanzlerplatz.

Nevertheless, the company is re-registered as a ready-to-work company on May 10, 1945 and resumes business operations in the remaining premises.

In the following years, SILICA concludes several contracts to rebuild the solvent recovery plants dismantled by the Allies.

The foundation stone for the reconstruction of the SILICA Gel company is laid!

By the time of the currency reform in 1948, the company had regained its full freedom of movement.

In addition to the necessary premises and machinery, it also has sufficient working capital.

As the expropriation of the SILICA Gel factory in Coswig was imminent, work began in 1950 on the construction of a new adsorbent factory in Bad Homburg, which was repeatedly expanded over the next few years.

At the end of 1956, Fritz Krull retires as a co-partner due to a serious illness.

Sale to the US company Grace

From 1962, the US company Grace proves to be a strong competitor for the production of silica gel.

As a result, the SILICA management decides to sell the factory in Bad Homburg and conclude a supply contract with Grace.

The proceeds from the sale are used to finance the construction of a new plant in Rosbach, Hesse.

Dr. Kurt von Lüde takes over the management of the new plant, but leaves the company at the end of 1965 due to illness.

Adolf Koopmann is now the sole owner of the company.

Due to the very positive development of orders, the plant in Berlin-Spandau is further expanded in 1966 and the company continues to grow.

Following the sale of Silica Gel production, SILICA Gel Gesellschaft now concentrates on the design and construction of systems for gas purification and solvent recovery.

With great success: in 1978, a new heavy construction hall is built at the Spandau plant.

After the death of Adolf Koopmann on February 24, 1979, his son Günter takes over the helm of the SILICA Gel company.

He guided SILICA with a steady hand through some stormy times: At the beginning of the nineties, SILICA faced major challenges due to the abolition of economic development funding for West Berlin after the fall of the Berlin Wall.

In addition, as a result of reunification, a large number of East German equipment and plant manufacturers enter the new all-German market with extremely favorable offers.

Realignment

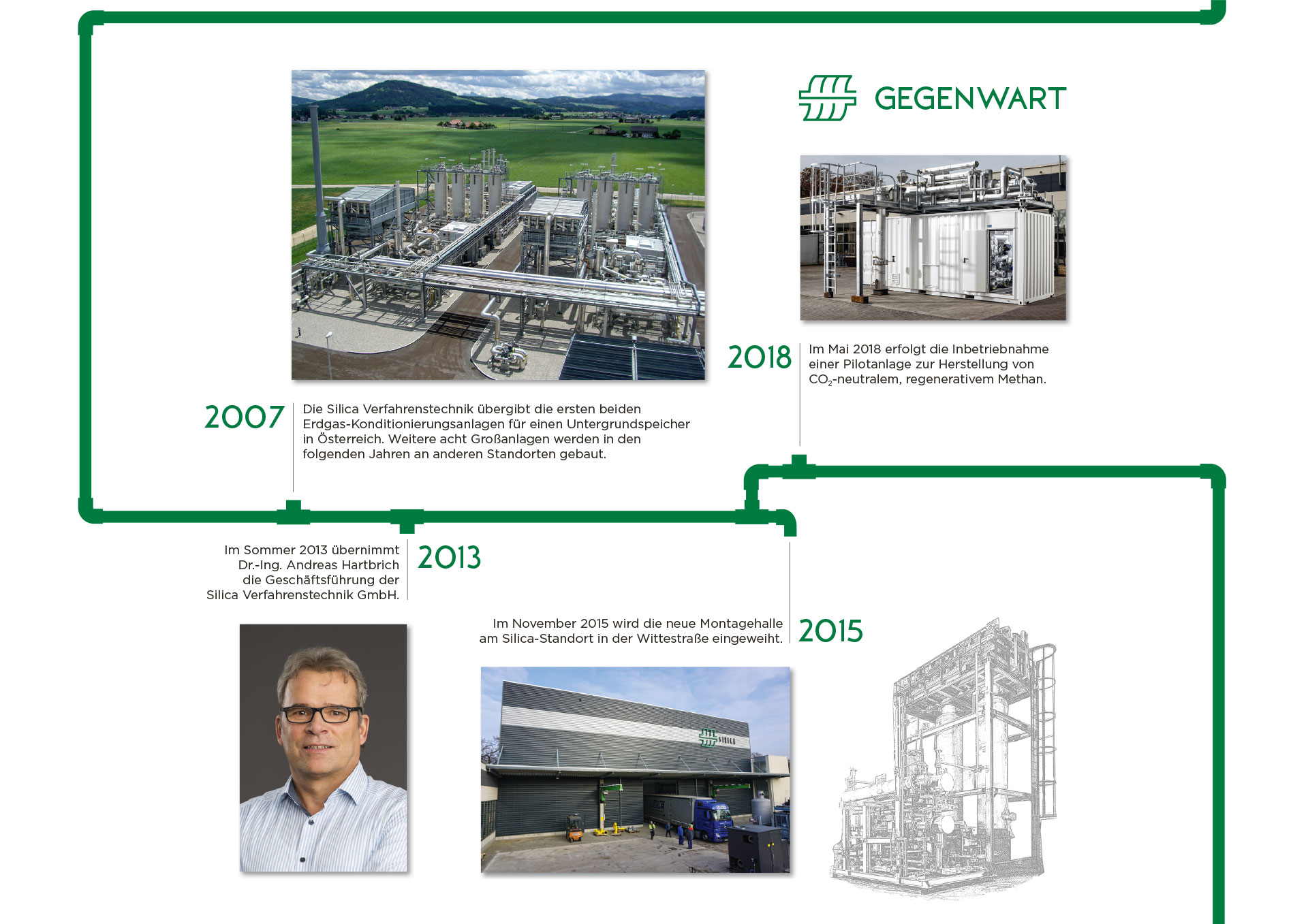

In 1990/91, Günter Koopmann took the decisive step towards further developing the company and securing its future: SILICA Verfahrenstechnik GmbH and SILICA Anlagenbau GmbH & Co KG were founded under the majority shareholding of the Austrian company Berndorf AG.

On the occasion of his 65th birthday, Günter Koopmann steps down from the management board in 1992 and remains available to SILICA on the advisory board in the following years.

In 1991, Hans-Joachim Redlich takes over the management of the company and leaves a lasting mark on SILICA.

Three years later, the company moves to its current location at Wittestraße 24; the existing office building is enlarged with an extension.

With systems for natural gas conditioning, SILICA succeeds in entering the large-scale plant construction sector with individual orders worth up to 22 million euros.

Part of the income generated is invested in expanding production capacity: in November 2015, a new assembly hall is inaugurated in Wittestraße, which, with its height of 14 meters, enables the indoor assembly of larger systems regardless of the weather.

Outlook for the future

Following the retirement of Hans-Joachim Redlich in 2014, the company is once again facing changes: The gradual transformation of the economy from fossil fuels to renewable energy sources brings many challenges for SILICA, but also great opportunities.

Hydrogen produced from renewable energies will establish itself as an industrial energy source in the coming years.

Small quantities of hydrogen produced from natural gas are already being replaced by “green” hydrogen.

SILICA’s purification and drying technology is used in the electrolysis plants of well-known manufacturers.

Together with our partner in Barcelona, we offer small, decentralized natural gas liquefaction plants to convert energy production from coal and diesel to the more environmentally friendly liquid gas in Southeast Asia and South America.

In addition, we will return to our old strengths and use new technologies to become much more active in the field of cleaning and recovering valuable materials from exhaust gas streams in order to conserve valuable resources.

Your contact to SILICA

SILICA: INDIVIDUAL, COMPETENT, RELIABLE

We treat every inquiry confidentially and conscientiously.

We want you to be completely satisfied with our work!